Control System Design, Integration and Upgrades

Control systems are designed and built upon open architectures, using proven tools to provide real-time data in a robust and secure environment. We offer our customers technically advanced, customized solutions backed by several years of industry experience and knowledge.

Our approach to control system design, integration and upgrades is centered around the customer’s needs and specification. After carrying out a thorough survey and giving our expert advice and opinion, we proceed with application engineering to develop a proposal for the customer’s review.

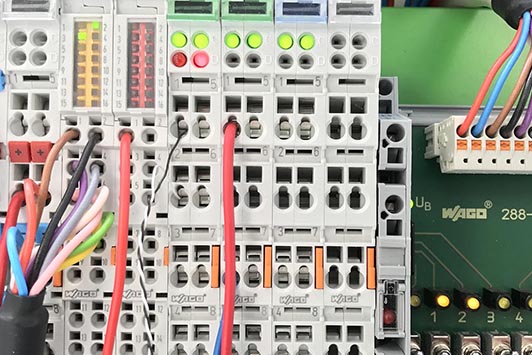

Upon acceptance, we begin the design engineering phase of the project which includes schematics, layouts, device lists, PLC programming, and HMI screens. Once that is complete, we proceed to the design and build phase where we construct or procure the control panel(s) and associated equipment and instruments as per design and specification.

The panel is tested at our facility to ensure that it meets the required IEC and other relevant standards, after which it is dispatched to the field for installation and commissioning. Finally, we are there for the life cycle support of the control system.

We understand control systems design, integration and upgrades as this is one of our many areas of expertise. This along with our wealth of experience and resources ensures that we always deliver Creative, Affordable, Reliable, Efficient and Smart solutions when it comes to control systems design, integration and upgrades.